PolyCera® is a new polymeric material platform derived from Nobel Prize winning polymer chemistry developed into membrane materials at the University of California, Los Angeles (UCLA) and the California NanoSystems Institute (CNSI).

PolyCera polymer materials are 100% organic, but they exhibit unique electronic behavior that shifts from metal-like conducting to metal oxide-like semi-conducting to plastic-like insulating properties. These materials are neither conventional polymers nor are they traditional metals or metal-oxide ceramics. PolyCera goes beyond traditional polymeric and ceramic materials.

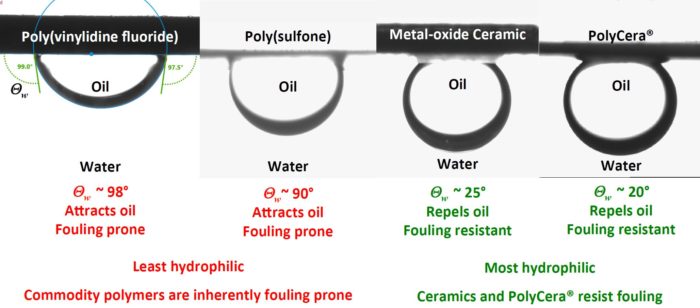

PolyCera membranes offer a unique combination of extreme hydrophilicity, permeability and robustness. Improved hydrophilicity means improved fouling resistance and ease of cleaning, ultimately, more water and less cost. Captive bubble contact angle using a pure hydrocarbon oil droplet, as shown below, measures the extent to which the oil droplet can displace water and stick strongly to the membrane surface. The lower the angle, the more the membrane favors water, resists fouling and cleans easily.

PolyCera membranes were developed to extend the range of polymeric membrane filtration to tackle the most challenging applications, delivering stable performance even under extreme pH, temperature, fouling and chemical conditions. This means low energy and high sustainable flux operation with extended membrane life, maximum system uptime, and minimal residual waste to manage.

News

-

PSP.US, Inc. Acquires Assets of PolyCera, Inc. and Pledges Commitment to Future of Company and Its Advanced Membrane Products

LOS ANGELES, July 15, 2020 – PSP.US, Inc. has acquired the assets of United States membrane company PolyCera, Inc., which in 2018 began the eagerly anticipated commercialization of its award-winning and highly differentiated organic metal membrane ...

-

PolyCera® Membranes Receive FDA Approval for Use in Food Processing Applications As Well as Certification to NSF/ANSI 61

Development Opens Door to New Markets and Applications for PolyCera’s Breakthrough Membranes LOS ANGELES, February 26, 2019 – PolyCera, Inc., which designs and manufactures innovative membrane technology solutions serving the global water, wastew...

-

PolyCera® Announces Distribution Agreement with Inaqua Vertriebsgesellschaft mbH

PolyCera, Inc. has signed a rolling two-year distribution agreement with Inaqua to represent its highly differentiated portfolio of membrane products in 25 countries throughout Europe, the Middle East and North Africa....

Proprietary PolyCera membrane line includes:

PolyCera Hydro

For OEMs, integrators and owner/operators who struggle to maintain high water throughput in tap water filtration, our PolyCera® Hydro product is a sub-20 nm UF membrane that delivers 6:4:3 log removal (bacteria: virus: protozoa) with high sustainable flux operation, fouling tolerance and ease of cleaning.

- Markets: drinking water treatment (TSS, turbidity, pathogens)

- Applications: POU/POE, surface water, seawater, groundwater

- Competitive Comparison: PolyCera Hydro versus PES and PVDF

PolyCera Titan

For OEMs, integrators and owner/operators who struggle to apply membrane filtration in industrial wastewater treatment, our PolyCera® Titan product is a sub-5 nm pore size UF membrane that delivers next-level oil, hydrocarbon, pH and temperature stability with high sustainable flux operation and ease of cleaning.

- Markets: industrial wastewater (oily, extreme pH, high organics, high-temp)

- Applications: produced water, acid mine drainage, refineries, food & beverage

- Competitive Comparison: PolyCera Titan versus PAN and ceramics

Spiral Monolith®

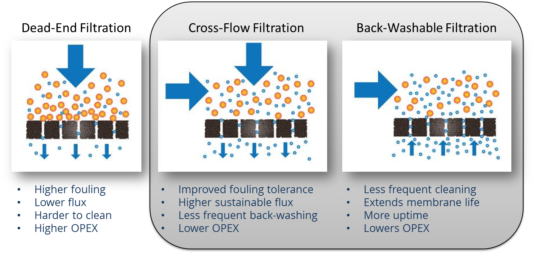

PolyCera membranes are offered in our proprietary Spiral Monolith® module, which enables either dead-end (low-energy) or cross-flow (high-fouling) operation combined with hydraulic backwashing. The result is that our Spiral Monolith modules with PolyCera membranes inside maximize process uptime and water recovery and minimize energy and operating cost.

FEATURES

- Super hydrophilic material

- High sustainable flux

- Fouling resistant and easy to clean

- Extreme pH, temperature and oxidant stability

- High tolerance for oil, COD/BOD, NOM and other solvents

- Surface properties inhibit biofilm formation

- Cross-flow modules minimize accumulation of fouling materials

- Back-washing removes deposited fouling materials

BENEFITS

- 10x lower cost than commodity ceramics

- Low energy demand

- Less process downtime

- Maintains permeability longer (low irreversible fouling)

- Handles the most challenging waters

- Easy to clean

- Reduces energy consumption

- Saves chemicals

- Lowers operating costs

APPLICATIONS

- Industrial wastewater treatment, recycling and reuse

- Tertiary treatment of municipal wastewater for non-potable reuse

- Conventional air and high-purity oxygen membrane bioreactors

- Drinking water filtration and point-of-use water purification

- Pre-filtration for brackish and ocean water desalination